- 1.5Mtpa processing plant and associated infrastructure

- Maggie Hays Resource Ni 52kt Ni at 1.5%

- Abi Rose Ni discovery confirms prospectivity

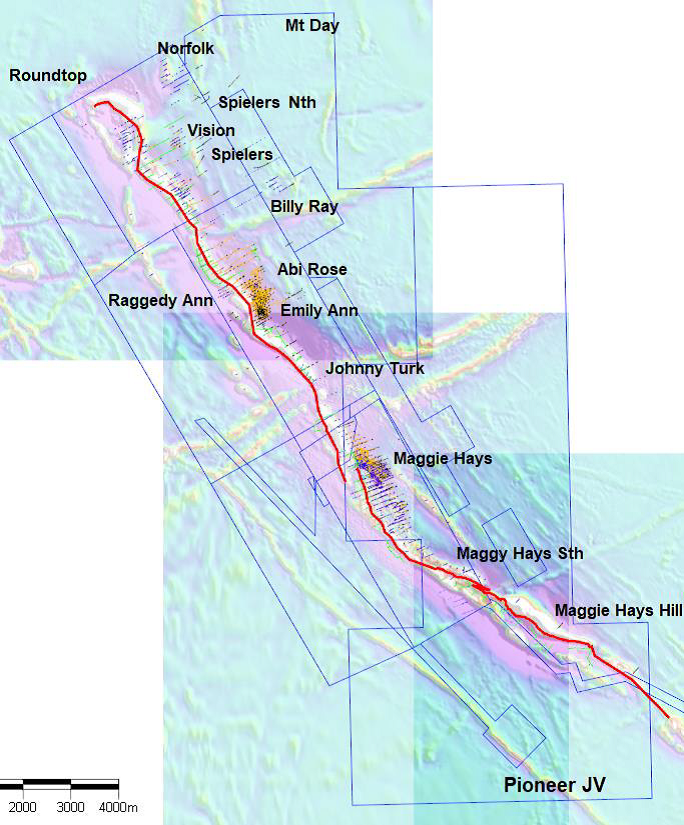

- Western Ultramafic Unit targets identified along 17km strike length

History

- Emily Ann - 1.5Mt @ 3.5% Ni mined and processed b/n 2001-2007

- Maggie Hays - 10Mt @ 0.6%Ni mined and processed b/n 2008-2014

Poseidon have identified and designed a number of exploration programs to test the upper surface of the Western Ultramafic Unit looking for Kambalda-style nickel deposits (see figure below).

The Lake Johnston project is considered highly prospective for further nickel discoveries. Future exploration works will focus on building resources to facilitate a recommencement of mining and processing operations, leveraging off the 1.5Mtpa processing plant and associated infrastructure located on site.

Future Operations & Processing Plant Refurbishment

Lake Johnston has the potential to be restarted as a second processing hub following successful exploration programs and an FID for the Black Swan Project.

Exploration activities are planned to grow Lake Johnston’s mineral resources and reserves, potentially supporting a recommencement of operations. GR Engineering Services Limited (“GRES”) was engaged to provide the Company with capital and operating cost estimates for the refurbishment and operation of the ore treatment circuit and associated infrastructure at Lake Johnston (to a +/- 20% level of accuracy).

The 2022 estimated capital expenditure to refurbish the plant and associated infrastructure was approximately $31 million with an estimated refurbishment timeframe of seven months, assuming power supply can be supplied and installed within this period.

The estimate of operating costs was $36.04 per tonne at a processing capacity of 0.9 million tonnes per annum. Ore would be treated through the existing crushing, grinding and flotation circuit of the Lake Johnston plant to produce a nickel concentrate.

Exploration

Studies on the Maggie Hays deposit at Emily Ann indicate both deposits were emplaced within a felsic volcanic sequence by a series of intrusive ultramafic magmas that collectively form the Central Ultramafic Unit (CUU). The CUU and felsic volcanic sequence are capped by a regionally persistent banded iron formation (BIF). The intrusive emplacement model for the deposits was confimred by the discovery of significant nickel sulphide mineralisation within an interpreted narrow feeder zone to the Emily Ann deposit at Abi Rose (refer to Poseidon ASX announcements “More Nickel Sulphides Intersected at Abi Rose” dated 22 November 2018 and “Significant High Grade Nickel Intersection at Emily Ann North” dated 25 January 2016).

The Western Ultra Mafic Unit (WUU) overlies the regionally persistent BIF sequence and is interpreted to have been emplaced as a series of extruded ultramafic flows by the CUU magmas breaching through the BIF sequence. The basal contact of the WUU is considered a high priority target for potential economic nickel sulphide mineralisation that has historically been overlooked.

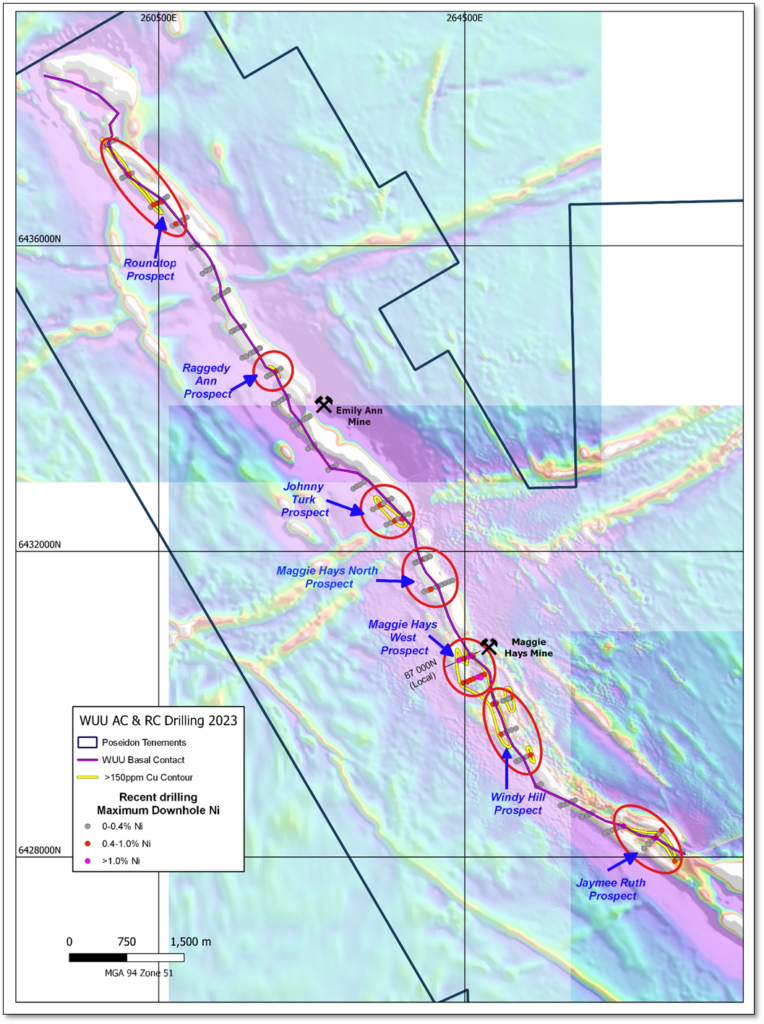

The WUU structure has been identified along 17km of strike. An initial program of shallow air core (AC) and reverse circulation (RC) drilling to delineate 14km of the interpreted overturned basal contact of the WUU has been completed. (refer to Poseidon ASX announcements “Exciting Greenfields Nickel Intersections at Lake Johnston” dated 3 July 2023 and “Projects and Exploration Update” dated 14 September 2023)

The aim of the programs was to both map the interpreted WUU basal contact and the channelised embayed features that are prospective for the accumulations of nickel sulphide mineralisation at its base and against the basal contact position as observed in Kambalda-style nickel sulphide deposits. Deeper RC holes will aim to provide critical geochemical information about the host rock fertility beneath the weathering profile and about the mineralisation of the basal contact.

Assay results from the reconnaissance drilling along the WUU has returned coincident nickel sulphide pathfinder (Ni:Co:Cu) anomalous zones within the weathering profile at seven separate prospects, including Roundtop, Raggedy Ann, Johnny Turk, Maggie Hays North, Maggie Hays West, Windy Hill and Jaymee Ruth.

The pathfinder anomalism includes Ni > 0.4% (at times Ni > 1.0%), Cu >150ppm and Co >500ppm have also been confirmed over prospective cumulate phase ultramafic rocks at various locations along the belt.

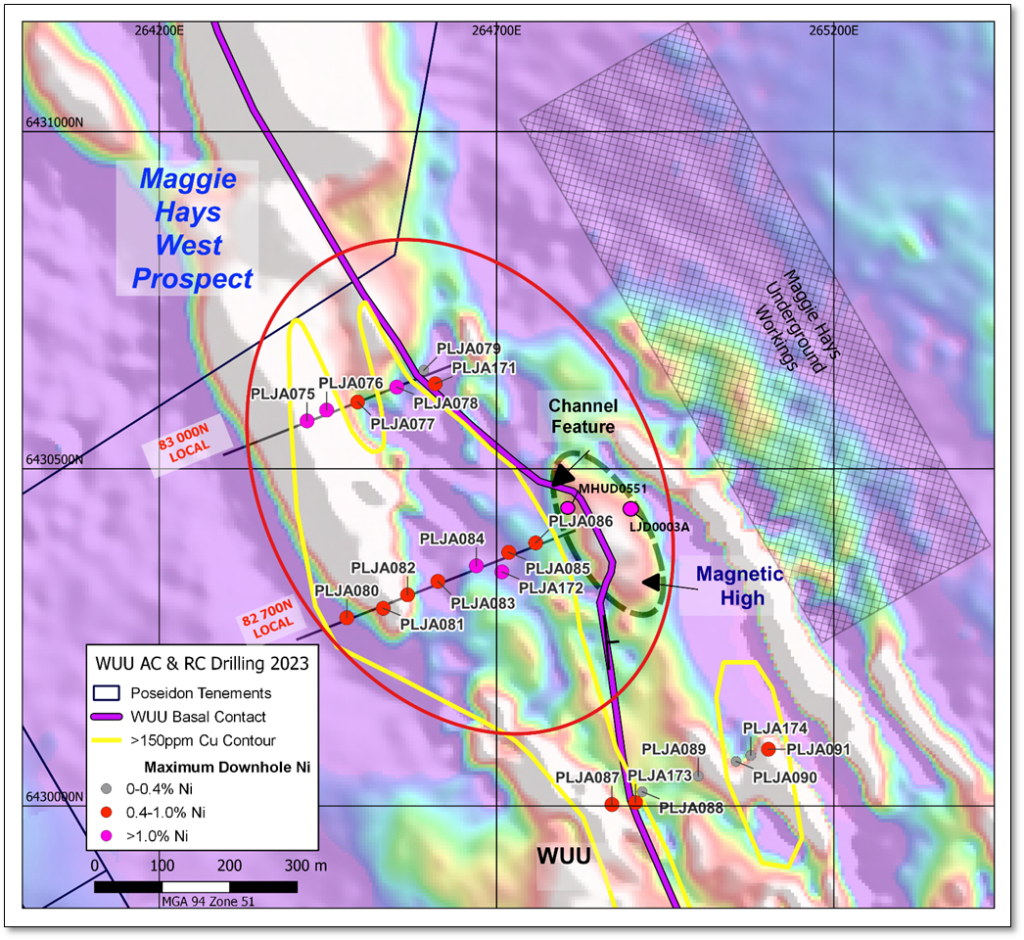

Maggie Hays West

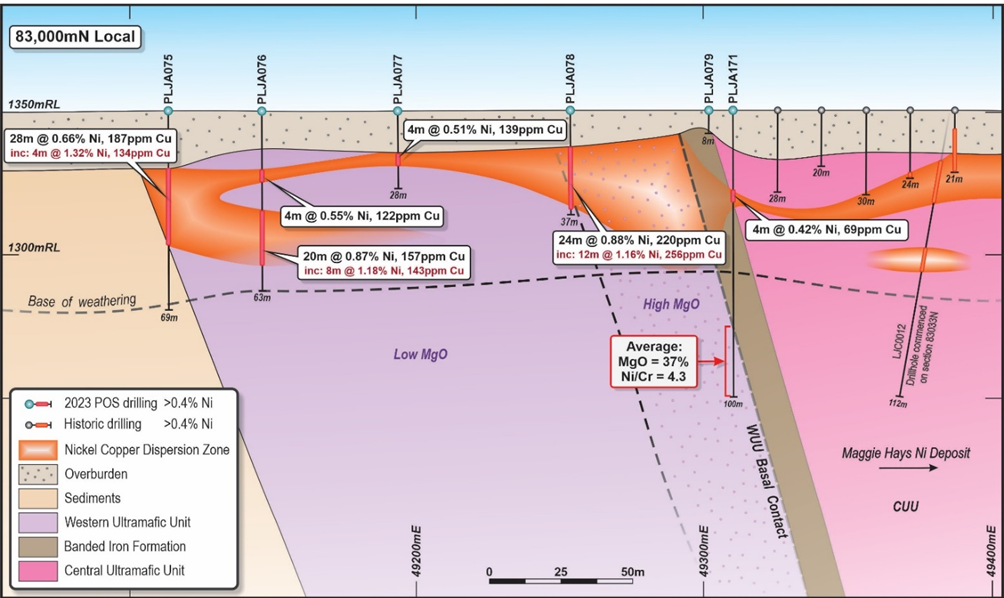

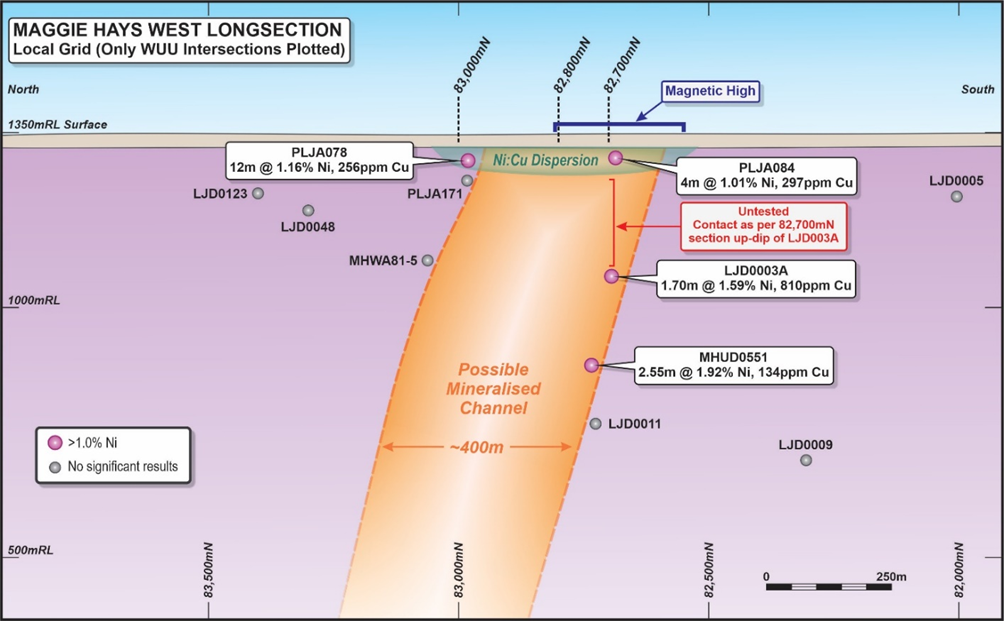

Verification of several positive attributes in the latest drilling phases have upgraded the prospectivity at the Maggie Hays West Prospect. These positive attributes include the confirmation of Ni:Cu regolith anomalism up dip from isolated historic nickel sulphide drill intersections. The drilling has also confirmed the thickening of the WUU to 300 metres on drill line 82700N (local grid) and the development of an embayed contact due to a possible channel feature.

One RC drillhole (PLJA171) was drilled through the basal contact in the recent program at Maggie Hays West returning MgO values averaging 37% (max. 41% MgO) and Ni/Cr ratios averaging 4.3 which is indicative of fertile channel facies ultramafic cumulate rocks at the base of the thickened WUU .

Maggie Hays West - Section 83 000N (Local Grid), showing recent and historic drilling with >0.4% Ni intersections, Ni/Cu dispersion and high MgO basal flow

When all these positive attributes are collectively compiled onto a long section projection, a possible mineralised, open ended channel target can be inferred at the Maggie Hays West Prospect that is up to 400m wide and corresponds to a discrete magnetic feature. The interpretation presents a compelling high priority target that warrants further drilling.

Maggie Hays West Long Section with WUU Basal Contact intercepts plotted only. Note the inferred mineralised channel opportunity is largely untested.

Regional Targets

Drilling has also defined six other targets for follow up with anomalous nickel present near the basal WUU contact. This includes the newly identified Windy Hill and Jaymee Ruth prospects. At Windy Hill elevated Ni:Cu trends have been intersected in close proximity to the BIF with limited drilling in the area. Significant Windy Hill intersections include:

- PLJA087 16m @ 0.55% Ni, 133ppm Cu from 28m

- PLJA091 16m @ 0.44% Ni, 152 ppm Cu from 4m and 20m @ 0.7% Ni, 112ppm Cu from 20m

- PLJA140 12m @ 0.46% Ni, 329 Cu from 8m and 4m @ 0.48% Ni, 812ppm Cu from 24m (EOH)

Similarly, the new prospect at Jaymee Ruth located in the south of the tenement holding has been identified with elevated Ni:Cu ratios at the basal contact along a 800m geochemical anomaly. Significant intersection include:

- PLJA116 8m @ 1.04% Ni, 126ppm Cu form 12mincluding 4m @ 1.23% Ni, 125ppm Cu from 12m

- PLJA124 4m @ 0.41% Ni, 199ppm Cu from 16m (EOH)

Roundtop, Raggedy Ann, Johnny Turk and Maggie Hays North prospects have all returned anomalous nickel and further assessment is required on all six prospects.

Next Steps

The results provide increased confidence in the geological setting and prospectivity of the WUU. Further sampling of the anomalous zones to one metre re-splits have been taken to delineate the anomalous intervals and will include analysis for PGEs. This will aid in the planning for infill and follow up drilling at the identified prospects, along with testing along the further southern 4km extension of the WUU.